All blogs

Industrial IoT

January 7, 2019

Manvitha

Industrial IoT

What Is Industrial IoT?

Everyone is well-aware of IoT which is nothing but connecting devices using the internet. IIoT (Industrial IoT) uses a similar concept where the machinery is connected using the internet with the help of advanced analytics platforms.

Difference between IoT and IIoT

Even though IIoT is a sub-category of IoT, the latter is used in the commercial sector where IIoT is used in the industrial sector. IIoT focuses on industrial applications whereas IoT is about connecting smart devices using the internet where humans interact more like home appliances. IIoT is used in the industries it determines the working condition of the machinery by keeping the supervisors updated with the current state.

Evolution of Industrial 4.0

Industrial 4.0 is an advanced version of IIoT. From the first industrial revolution (mechanization through water and steam power) to the mass production and assembly lines using electricity in the second, the third is the adoption of computers and the fourth industrial revolution will be the automation and enhancement of its previous revolution concepts. It works with the enhancement of smart and autonomous systems fueled by data and machine learning.

What is Industry 4.0

Industry 4.0 is the current trending industrial revolution. It is a combination of automation, data, cyber-physical systems, the Internet of Things and the Internet of Systems. The cyber-physical systems used will monitor the physical operations in industry and communicate with one another to ultimately make decisions without any human involvement.

Must Read: Iot and Performance

Why Industrial IoT?

It is very much useful for the industries that involve logistics operation. IIoT would definitely be a game-changing concept in the business. Majorly it works on facility management where the users are notified if there is going to be any wear and tear in the machine in near future.

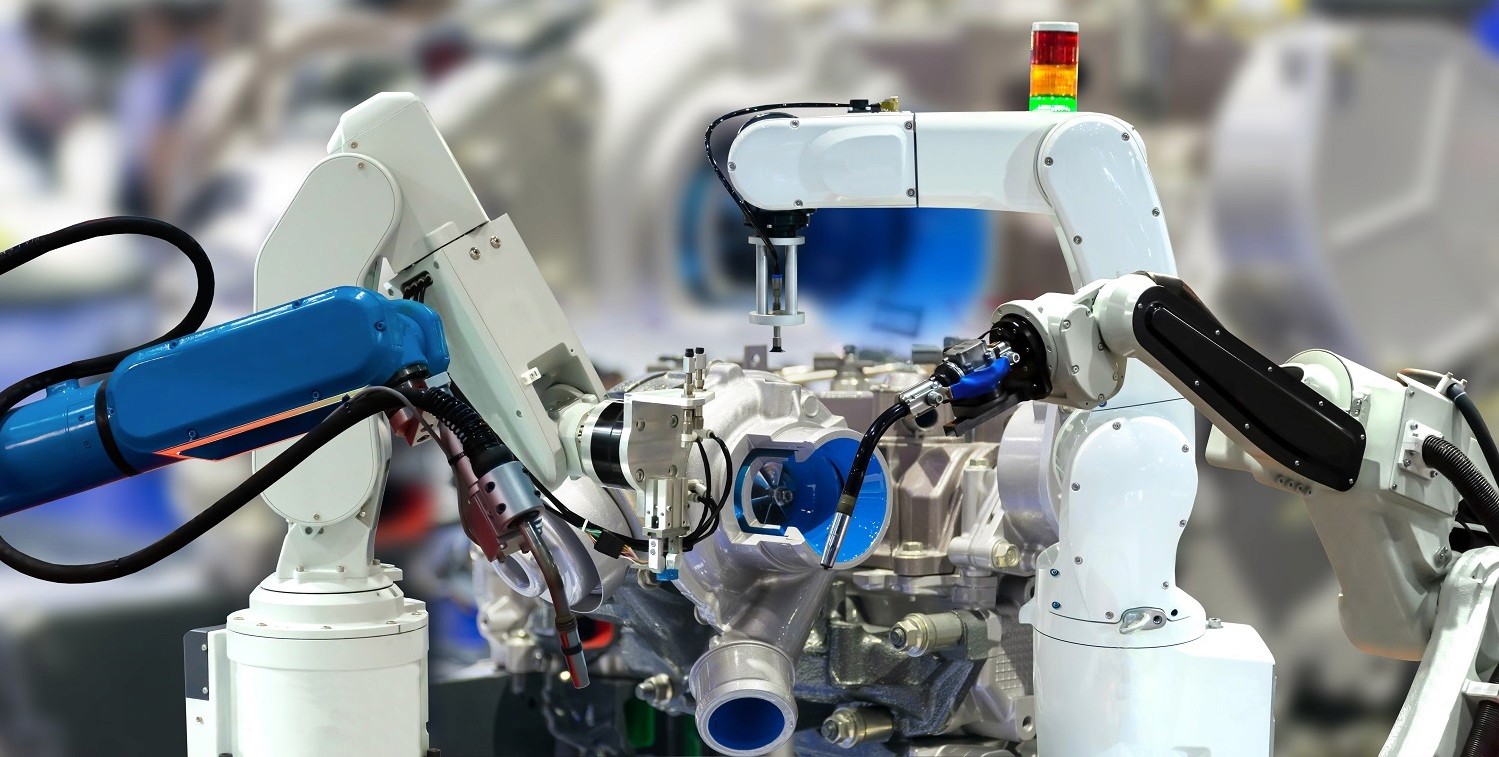

How IIoT helps in increasing production

The concept of “precaution is better than cure” is widely used in IIoT. When a machine is working under the supervision of IIoT, it keeps an eye on the working condition where the history of breakdowns is noted as well. It analysis the machine behaviour and predicts the next breakdown. Through this, the supervisor can check and prevent it from wear and tear.

IIoT Across major industries

IIoT in manufacturing – In any industry, it is important to maintain a budget and cut down costs at unnecessary places. IIoT will help in such asset management. It checks the machine health from time to time and generates some graphs through the detailed analysis it notifies the user if any breakdown is going to happen.

IIoT in connected logistics and transportation – It works as a communication mesh for different areas connected to a central warehouse. It monitors the supply chain and also helps in tracking the vehicle.

IIoT in energy and utilities – It helps in the working of the plant effectively and its maintenance with time to time analysis.

Must Read: Connected vehicles

IIoT Technologies and concepts

Intelligent Edge devices – It uses intelligent devices like edge gateways, sensors which alarms the supervisor regarding the breakdown of the machine.

Edge Computing – Initial data processing in edge devices in the cloud will be expensive so IIoT allows this computing at the premises of the operational area with the help of edge gateways.

Digital Twins – As soon as a machine is registered on IIoT application, it creates a virtual twin of each machine which makes it easy to predict the working condition using the digital twin.

Device shadow – It is generally a JSON store that stores the state of the devices which will be updated periodically. Device shadow helps in retrieving the last known state of the device when the connection is lost/interrupted.

Data Analysis – The data generated from different sensors are stored in various formats. This data will be filtered, aggregated, analyzed to generate insights on the working condition of the machine.

Insights – Real-time graphs are generated through which working condition is predicted and the real-time alerts are generated as well when the machine has deviated from the standard values.

Must Read: 5 Benefits of IoT – for “We, The People”

Preventive Maintenance with IIoT

The primary use of IIoT application in industries is the preventive maintenance. It identifies the failure in the machine in prior by comparing with the historical data analysis and insights.

How preventive maintenance is done with IIoT

When the sensors are attached to a machine the working condition is inspected from time to time.

This data is sent to an edge gateway where there would be an initial data cleaning done which excludes the unnecessary information.

The filtered data will be sent to the cloud from the gateway. Here the data analysis is done where the current generated values are compared to the standard values.

The standard values are generated from the historical data.

If the current values deviate from the standard values, the supervisor will be alerted immediately.

Benefits of IIoT

Improving operational efficiency

Improving productivity

Creating new business opportunities

Reducing downtime

Maximizing asset utilization

Real-Time Monitoring

Preventive Maintenance

Must Read: 5 Business Benefits of IoT

IIoT Major Challenges

Data Integration – Data integration is the biggest challenge in the IIoT application as data is generated from different sources and formats there must an explicit logic used to clean the data and integrate it.

Lack of skills – There is a lack of skilled people who can supervise the IIoT application.

Cybersecurity and Data security – Handling huge data is definitely not a piece of cake walk. The data needs to be secured which requires a good encrypted algorithm to secure streaming data and store it.